Explore Track Rollers: Complete Guide, Basics, and Essential Knowledge

Track rollers are critical components in the undercarriage system of crawler-type machinery such as excavators, bulldozers, and tracked loaders. They are positioned beneath the machine’s frame and guide the movement of the track chain, supporting the machine’s weight as it travels across different surfaces.

Unlike wheeled machines, crawler equipment distributes weight across tracks. This design improves traction and stability on soft, uneven, or muddy ground. Track rollers exist to manage the constant motion and heavy load transfer between the track chain and the machine frame. Without them, friction would increase, movement would become unstable, and undercarriage wear would accelerate.

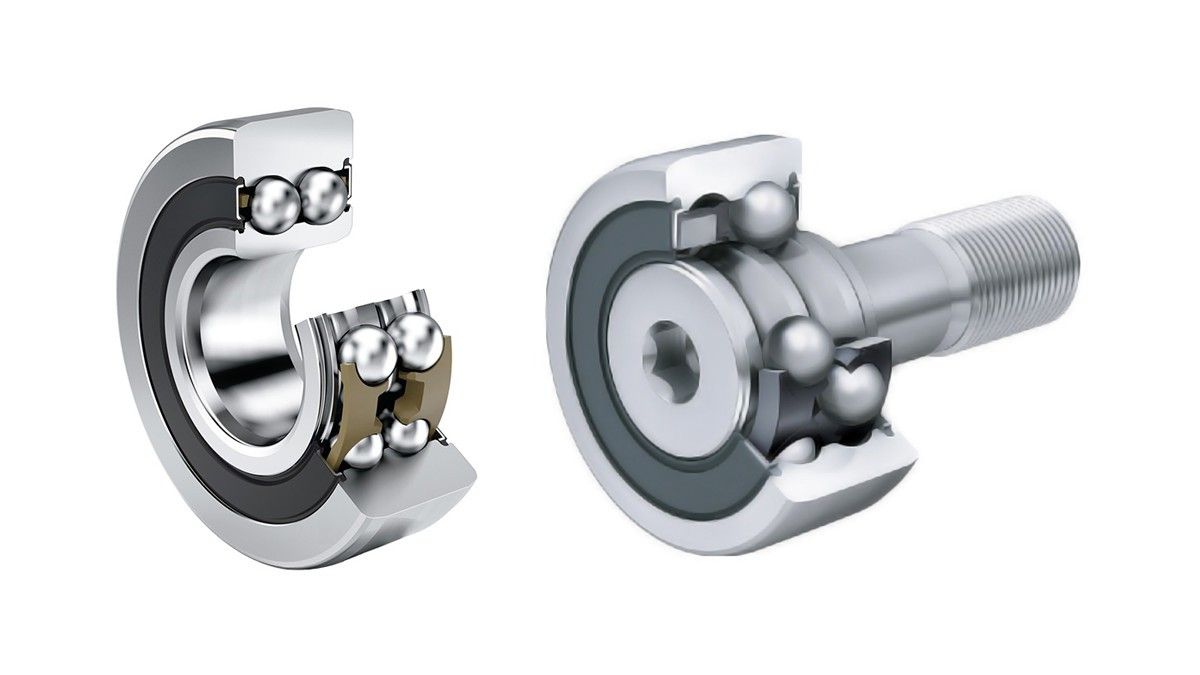

Track rollers typically consist of hardened steel shells, internal bushings, seals, and lubrication systems. They are engineered to withstand heavy pressure, vibration, and harsh environmental conditions. In industrial machinery engineering, they are considered part of the core undercarriage performance structure.

Common equipment using track rollers includes:

-

Hydraulic excavators

-

Bulldozers

-

Crawler cranes

-

Forestry machines

-

Mining equipment

Their design varies depending on machine size, terrain type, and load requirements.

Importance – Why Track Rollers Matter Today

Track rollers play a major role in construction equipment efficiency and durability. As infrastructure projects expand and heavy machinery operates in more challenging environments, the reliability of undercarriage components has become increasingly important.

Key reasons track rollers matter:

-

They distribute machine weight evenly across the track system

-

They reduce friction between the track chain and frame

-

They enhance stability on slopes and rough terrain

-

They support fuel-efficient movement by minimizing resistance

-

They contribute to longer equipment lifespan

In many tracked machines, the undercarriage accounts for a significant portion of maintenance planning. If track rollers fail or wear unevenly, the entire undercarriage system can be affected, including sprockets, idlers, and track chains.

Industries affected include:

-

Construction and infrastructure development

-

Mining and quarry operations

-

Agriculture and land clearing

-

Forestry and environmental management

-

Industrial logistics in off-road conditions

Track rollers help solve practical challenges such as ground pressure control, traction stability, and load distribution. In regions with heavy rainfall or loose soil, crawler systems with efficient rollers provide better operational continuity than wheeled alternatives.

Below is a simplified comparison of crawler systems versus wheeled systems:

| Feature | Crawler System with Track Rollers | Wheeled System |

|---|---|---|

| Ground Pressure | Lower | Higher |

| Traction on Soft Soil | Strong | Moderate |

| Stability on Slopes | High | Medium |

| Urban Road Mobility | Limited | High |

| Undercarriage Complexity | Advanced | Simple |

This comparison highlights why track roller systems remain essential in heavy-duty environments.

Recent Updates – Trends and Developments

Over the past year, several developments have influenced track roller design and undercarriage systems.

Manufacturers have focused on:

-

Improved sealing technology to prevent contamination

-

Enhanced heat-treated steel alloys for longer durability

-

Smart monitoring systems integrated with telematics

-

Reduced environmental impact through recyclable materials

Digital maintenance tracking has become more common. Some modern crawler machines now include condition-monitoring sensors that track vibration levels and wear indicators. These systems help operators plan maintenance more efficiently and reduce unexpected downtime.

There has also been increased emphasis on sustainability in industrial machinery engineering. Research into wear-resistant coatings and extended lubrication intervals aims to reduce material waste and environmental impact.

In large infrastructure projects, data-driven equipment management has become a trend. Telematics platforms can provide insights into undercarriage performance, including roller rotation patterns and load stress indicators.

Laws or Policies – Regulatory Influence on Track Roller Systems

Track rollers themselves are mechanical components, but they operate within regulated environments. Machinery used in infrastructure and mining projects must comply with equipment safety and environmental standards.

Key regulatory influences include:

-

Workplace safety standards requiring stable and properly maintained machinery

-

Environmental regulations addressing soil disturbance and emissions

-

Equipment certification and inspection programs

-

Occupational health rules related to vibration exposure

Government infrastructure initiatives often include equipment compliance requirements to ensure safe construction practices. In mining and forestry sectors, machinery must meet operational safety guidelines related to terrain stability and worker protection.

Maintenance documentation is also influenced by regulatory frameworks. Equipment operators may be required to maintain inspection records, especially for large-scale public projects.

These regulations encourage proper undercarriage maintenance and periodic evaluation of track rollers to reduce risks associated with mechanical failure.

Tools and Resources – Helpful Platforms and Technologies

Several tools and digital resources support track roller maintenance, monitoring, and performance evaluation.

Telematics systems from major equipment manufacturers provide real-time operational data. Examples include:

-

Caterpillar Inc. Product Link telematics platform

-

Komatsu Ltd. KOMTRAX system

-

John Deere JDLink monitoring platform

These platforms allow operators to track equipment usage hours, operating conditions, and maintenance schedules.

Additional resources include:

-

Equipment maintenance management software

-

Engineering reference manuals on undercarriage systems

-

Industrial standards publications

-

Predictive maintenance analytics tools

-

Training modules for heavy machinery operators

Common maintenance tools used in track roller inspection:

-

Ultrasonic thickness gauges

-

Torque measurement devices

-

Lubrication monitoring kits

-

Infrared temperature scanners

Using data-driven tools enhances heavy machinery maintenance insights and supports long-term equipment durability knowledge.

Frequently Asked Questions

What is the main function of a track roller?

A track roller supports the weight of crawler machinery and guides the movement of the track chain along the undercarriage. It reduces friction and helps maintain stability during operation.

How do track rollers wear out?

Wear typically occurs due to continuous load pressure, abrasive soil conditions, poor lubrication, and contamination from debris or moisture. Over time, the outer shell may develop surface marks or uneven edges.

How often should track rollers be inspected?

Inspection frequency depends on operating conditions. Machines used in mining or rocky environments may require more frequent checks compared to those used on softer terrain. Routine visual and performance checks are generally recommended as part of preventive maintenance.

Can worn track rollers affect fuel efficiency?

Yes. Increased friction or misalignment can cause additional strain on the engine and drive system, potentially reducing operational efficiency.

Are track rollers interchangeable between machines?

Track rollers are typically designed for specific machine models and load capacities. Compatibility depends on dimensions, load rating, and undercarriage configuration.

Conclusion

Track rollers are essential components within crawler undercarriage systems. They enable heavy machinery to move efficiently across challenging terrain while maintaining stability and structural integrity. As construction, mining, and infrastructure projects expand, the reliability of these components becomes increasingly important.

Advances in materials engineering, digital monitoring systems, and predictive maintenance technologies continue to improve undercarriage performance. Regulatory standards further emphasize safety, proper documentation, and environmental responsibility.

Understanding track rollers from both a mechanical and operational perspective supports informed equipment management decisions. With ongoing innovation and growing emphasis on industrial efficiency, track rollers remain a foundational element in modern construction equipment components and heavy machinery engineering systems.